Exact results with the right tools

We develop and produce in cooperation with experienced users reusable surgical instruments for various applications in orthopedic and trauma surgery.

Our instruments are manufactured in batches or as individual pieces and are suitable for use as medical products with certificate of origin.

Please contact us

Product portfolio

TORS system

Easy removal of bone cement with a special ultrasound technology. Wide range of probes for all possible applications.

more

OrthoClast system

Solution with pneumatic shock waves for both cementless and cement removal revisions. Cemented revisions with endoscopic view.

more

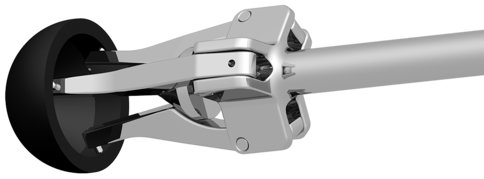

endocon hip revisions

Our universal usable instruments for hip revisions are precise and easy to use. Please have a look at them: endoCupcut, endoCupex and endoShaftex.

more

Loan service

Are you planning shortly a revision? Ask us for the needed instruments and take advantage of our loan service. Our team will be glad to assist you.

more

Support

We support you in answering your questions about the use of the instruments. Contact us, we look forward to your inquiry.

contact

Express service

They have an urgent revision surgery? You need the right instruments for explantation? With our overnight service you will get it just-in-time.

Express service